Shop Categories

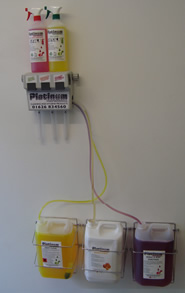

AccuDose

Description:

AccuDoseTM dispensers are an economical way to dispense a wide variety of automatically diluted solutions into spray bottles, buckets or other containers at the touch of a button. Dilution is controlled by drawing chemical through metering tips of varying size and injecting this metered amount into the water flow.

AccuDose dispensers use durable materials and state of the art water valve technology to provide low cost, consistent performance, and reliable service in a wide variety of customer environments. Users will also appreciate the ease of operation and low service requirements of the AccuDose line. Standard models are available with any combination of low and high flows in one, two and three product configurations. In addition, the linkable inlet and outlet fittings on AccuDose dispensers allow for more than three products to be dispensed, a larger dispensing system is created by simply joining the appropriate units together. And even after installation of the system, it can be expanded as new product needs arise. This versatility reduces stocking requirements while it increases the distributor's ability to respond to customer needs. And since each standard button can be converted to lockability in the field, customizing the standard systems to individual needs is simpler than ever!

Application:

- Robust cabinet, hygienic appearance, no hard edges.

- Small footprint.

- Positive button operation, with locking feature.

- Instantaneous shut-off with anti-water hammer.

- Recessed button less prone to dirt and damage.

- All European water authority approvals.

- Moulded plastic dispenser for up to 5 products.

- Easy to install, easy to use push-button operation.

- High or low flow.

- Automatically and accurately dilutes chemical concentrates.

- Options to customise.

AccuDose dispensers provide these benefits to any chemical management program:

Better chemical performance

- Consistently correct dilution ensures products perform as they were designed to.

Labor savings

- Employee time required to prepare solutions is greatly reduced.

- Additional labor required to make up for solutions that are too weak is eliminated, as well as re-work to restore areas damaged by solutions that were too strong.

Improved employee safety

- Exposure to potential eye and skin irritants through splashing and spilling when chemicals are poured is eliminated.

- Potential for back strain is reduced by limiting lifting of large chemical containers.

Environmentally friendly

- Accurate dilution prevents excess chemical discharge into the waste water system.

- Concentrating chemicals allows enormous reduction in packaging, minimizing additions to the solid waste stream.

Available Pack Size: